Environmentally Degradable Polymers

Introduction

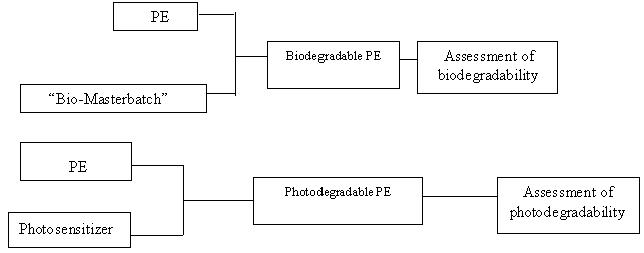

Polyethylene (PE) is used as commodity plastics in diverse applications such as packaging, personal hygiene products, construction, clothing, chemical plants, cables etc High volume usage of PE has resulted in concerns in plastic waste management. The problem is so immense that there is continuing research to develop a special grade of polyethylene which will be tailored to retain the service characteristics during its usage but will disintegrate into safer components on disposal. Addition of biodegradable and/or photo degradation promoting additive in PE are one of the few techniques used to design such products. However high cost along with low compatibility with PE has restricted the use of commercially available biodegradable polymers for wide spread application. The present work is an effort to develop cheap film formable polymeric component, which will disintegrate from PE matrix on disposal and thereby cause no littering of PE wastes and also to develop photo initiator to promote photo degradation of PE.

The process involves post reactor modification of polyethylene by incorporating biosoluble polymer or a photo degradation-promoting additive into the PE matrix. The project involves development of bio and photo-master-batch based on styrene maleic anhydride copolymer (SMA) and blending these components in PE at different proportion. The blended product is made into film by extrusion film blowing process, for the production of packaging material as well as carrybags. Testing and evaluation of the film is done by standard testing procedures.

Special Features

Biomasterbatch

- Can be made easily by cheap raw materials;

- Easy to synthesize;

- Hydrophilic in nature and hence expected to be biosoluble;

- Film forming polymer;

- Nontoxic in nature;

- Cheaper than commercially available biodegradable polymers such as aliphatic polyesters.

Photomasterbatch

- Easy to prepare;

- Polymeric in nature so no problem of leaching out on processing.

Status of Development

The development has been carried out with the production of 250 grms. per batch of environmentally degradable product. Batch time is approximately 5 hours.

Major Equipment & Facilities required

Jacketed reactor with heating arrangement, condenser and stirrer; Extrusion/Compounding machine for making granules; Film blowing machine

Requirement of Raw Materials/Components

Biomaster batch :Styrene

Maleic anhydride

Solvents

Developed by

Prof. K A Ghosh

Department

Center for Polymer Science and Engineering

For further information please contact

Managing Director

Foundation for Innovation and Technology Transfer (FITT)

Indian Institute of Technology, Delhi

Hauz Khas, New Delhi-110016, INDIA

Tel : 91-011-26597167, 26857762, 26581013, 26597153

Fax : 91-011-26851169

E-mail : drkdpn@gmail.com