Biodegradable Metal Working Fluid (Soluble Cutting Oil)

Introduction

Metal working fluids are important to engineering industry. Petroleum lubricating oil has been established themselves as major constituents of such lubricants. These are used on machine tool for the manufacture of engineering goods where the shape of final object is obtained by progressive removal of metal. In India nearly 50,000 Kilolitre of metalworking fluids, produced from mineral oil derived lube base stocks, are consumed annually.

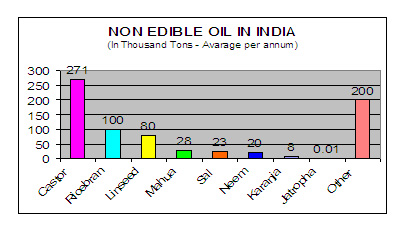

IIP-Dehradun has developed non-edible vegetable oil based fully biodegradable metalworking fluids that offers same or even better performance as petroleum oil based products. This metalworking fluid from renewable will be less expensive than petroleum oils and offers significant benefits to environment and to end-users.

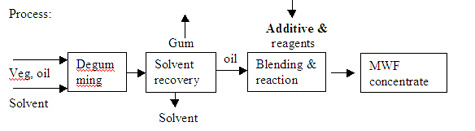

Composition and process for biodegradable metalworking fluids for its preparation based on vegetable oil and a biodegradable emulsifier to replace mineral oil and petroleum sulfonates. The vegetable oil based biodegradable metalworking fluid composition comprising of non-edible vegetable oil, one emulsifier which is a sodium carboxylate of vegetable oil, oleate, sulfonate or mixtures thereof, an antioxidant, a fungicide, an extreme pressure additive, an antirust, a co-surfactant, a coupling agent and alkali component. The process comprising of removing of insoluble matter from the vegetable oil, addition of emulsifier, additives, coupling agent and co-surfactant, homogenizing the mixture followed by conditioning of the metal working fluid concentrate, which can be used as emulsion in water.

Typical characteristics

| Standard - BIS 3065 | Soluble oil Specs | IIP lube |

| K.Viscosity-cst at 100° C | - | 5.30 |

| K.Viscosity-cst at 40° C, | 15/30 | 26. 37 |

| Viscosity Index, min | - | 145 |

| Dosage % by vol. | - | 20 |

| Evaporation loss at 40° C, % wt | - | 0.06 |

| Flash Point, ° C, min | >100 | 210 |

| Relative Density 20° C | To be reported | 0. 9403 |

| Sap. value, mg/KOH, min | 16 | 17. 5 |

| Copper strip Corrosion, max 3 hours-100° C | <1 | <1 |

| Iron chip corrosion, 24 hours | nil | nil |

| Emulsion stability, 24 hours | Pass | Pass |

| Reactive sulfur | nil | nil |

| Ash Sulphate %, max | 0.01 | 0.008 |

| TAN, mg KOH, max | 7 | 0. 055 |

| Deposit- panel cocker, mg, max | 4 | |

| Wear Scar Dia, mm | 0. 383 | |

| Weld load, Kgf | 140 | |

| Friction coefficient, mm | 0. 065 | |

| Biodegradability % | >98 |

- Patent: Indian patent application filed

- Benefits

- Reduces use of petroleum

- Offers better use of non-edible oils

- Reduce break-down period

- Produces fewer pollutant waste

- Product is almost completely biodegradable

- Safe to use

- Provides better Lubricity and extends tool life

- No health hazards due to toxic mist and effluents

- Helps in employment generation and rural upliftment

- Reduce environmental problems when spills (rapid biodegradable & non-toxic)

- Safe ( high flash & fire point, less volatile, food grade & contain no poly-cyclic aromatics, non-toxic)

- Compatible with mineral oil and its equipment

- Excellent lubricity enhancer

- Renewable

- Single compound, easy to characterise

- Reduce dependence on mineral oil - energy security

Applications

There is a large market of Biodegradable ecofriendly soluble oil in metalworking industries in India as well as in abroad also. There exists huge potential for use as neat oil metalworking.

Comparison of properties of various soluble cutting oil

SNo. |

Properties |

Conventional |

IIP Product |

Remarks |

| Mineral | Veg. Oil | |||

| 1 | Performance tests | Pass | Pass with high lubricity | Better |

| 2 | Disposal | Recycle, treatment | Negligible | Better |

| 3 | Operator friendly | No | Yes | Better |

| 4 | Biodegradability % | 20-40 | 94-98 | Better |

| 5 | Renewable source | No | Yes | Better |

- Suggested minimum plant capacity: 50 tons per annum

- Likely investment: ~ Rs.30 lacs

- Product cost: Rs.100/- per kg

- Pay back period: ~ 2 years

- The technology has been filed for Indian patent and is ready for transfer.

For further information please contact

Director

Indian Institute of Petroleum

P.O. IIP, Mohkampur

Dehradun - 248005

Email: director@iip.res.in

Tel: +91 135 2660205

Fax: +91 135 2660098 / 2660202