Rice Husk Plastic Composite (Wood without tree)

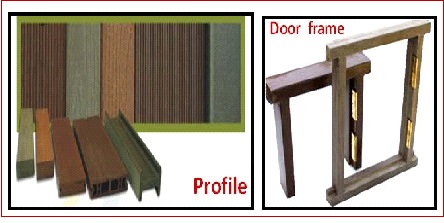

Applications

Window & door frames, profile panels, decking, fencing, flooring, park benches etc.

Salient Features

Wood like surface appearance, dimensionally stable, biologically durable, easily recyclable, carpenter friendly, replacement of natural wood, meets requirement of NBC 2005, Sec 3, Timber.

Technology Package

Technical know-how produced on lab scale, right to use patent. Product hand book/ data sheet. Guidelines of setting of testing lab for Q.C. and other intellectual knowledge base related to project

Techno-Economics

Process know-how includes: rice husk flour production line, compounding line and profile extrusion line. The cost of developed products is comparable with the teak wood and alike.

Scale of Development

Pilot plant scale development

Status of Commercialization

Commercialized

Raw Materials

Rice husk, thermoplastic resins and additives

Plant, Equipment and Machinery required

Digester, k mixer/ k neader, extruder, engineering moulds and other ancillary items.

Environmental Aspects

To save deforestation and environmental aspects caused by cutting of trees, and Plastic wastes are being utilized in the process.

IPR Status

Indian Patent Application No. 2193/DEL/2008

For further information please contact

The Director

CSIR - Central Building Research Institute,

Roorkee – 247 667

Phone: +91 – 1332 – 272243